Clean Energy Transition

Vehicle electrification is a key enabler of the world’s clean energy transition. This has increased the demand for more power-dense Lithium-Ion battery technology and permanent magnet traction drive systems, resulting in the growing demand for critical metals, such as cobalt, nickel, manganese, copper, and rare earths.

The Role We Play

Moana Minerals is committed to sustainably providing these critical metals through the development of our nodule project to significantly address the projected shortfalls of these metals.

Learn More About Our MissionWhy are Metals Important for a Clean Energy Transition?

Cobalt, nickel, and manganese in particular enable the functioning of high-energy-density Lithium-Ion battery chemistries, while rare earth elements are integral to the most efficient electric vehicle traction drive systems, and copper is used extensively throughout electric vehicles. If we want to transition to electric vehicles, we must have enough of these metals.

The Metals That Drive

the Clean Energy Transition

Achieving “well below 2°C global temperature rise”, as in the IEA Sustainable Development Scenario, would need an estimated supply growth of 21X for cobalt, 19X for nickel, and 8X for manganese, and 7X for rare earths for clean energy technologies by 2040. Seafloor nodules provide an untapped source of some of these metals in a single ore deposit.

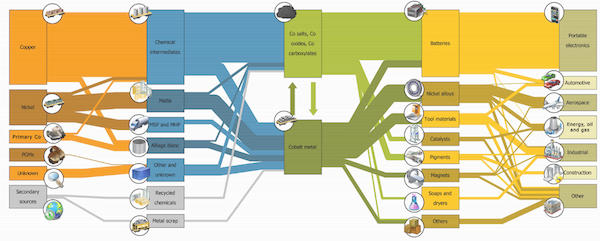

Cobalt is a key component of lithium-ion battery cathodes used in the majority of modern electric vehicles. Co provides for high specific power and long-life in electric vehicles, enabling high cycling rate, high capacity, and high power with the lowest self-heating rate of the different types of lithium-ion batteries. World Bank relevant low-carbon technologies include energy storage, coal, gas, and carbon capture and storage.

Cobalt

Cobalt is a key component of lithium-ion battery cathodes used in the majority of modern electric vehicles. Co provides for high specific power and long-life in electric vehicles, enabling high cycling rate, high capacity, and high power with the lowest self-heating rate of the different types of lithium-ion batteries. World Bank relevant low-carbon technologies include energy storage, coal, gas, and carbon capture and storage.

In 2020, total world production of cobalt was 140,000 metric tonnes with a 2019 market size of $8B. Historically, most cobalt has been used for Co-based superalloys, where it imparts temperature stability making them suitable for turbine blades in gas turbines and aircraft jet engines. Outstanding corrosion- and wear-resistant makes Co-based alloys ideal for orthopedic and dental implants, while increased heat and wear resistance makes Co containing high-speed steels suitable for cutting tool applications. Other specialty alloys containing Co are used to produce Alnico and samarium-cobalt permanent magnets.

Cobalt has been widely used in lithium-ion battery cathodes for consumer electronic devices such as mobile phones, laptops, tablets, power tools, and e-bikes. Nickel-cadmium (NiCd) and nickel metal hydride (NiMH) batteries also include cobalt to improve the oxidation of nickel in the battery. More recently, Co containing lithium-ion batteries have been used in the majority of modern electric vehicle. Their high specific power and long-life are enablers of electric vehicles, providing for high cycling rate, high capacity, and high power with lowest self-heating rate of the different types of lithium-ion batteries.

Cobalt compounds are used as catalysts in the production of polymers, paints, varnishes, inks, hydrodesulfurization of petroleum, and the hydrogenation of carbon monoxide into liquid fuels. They are used to improve the adhesion between steel and rubber in steel-belted radial tires and as accelerators in polyester resin systems.

Cobalt has been used since the Middle Ages as a color for glass and ceramics, and as a pigment for paints, inks and varnishes, and is still used today because of its superior chromatic stability.

Cobalt-60 is useful as a gamma-ray source because it can be produced in predictable amounts with high activity by bombarding cobalt with neutrons. It is used in external beam radiotherapy, sterilization of medical supplies and medical waste, radiation treatment of foods for sterilization, industrial radiography, density measurements, and tank fill height switches.

Other uses include electroplating for its attractive appearance, hardness, and resistance to oxidation, as a base primer coat for porcelain enamels, and Cobalt is also a bio-essential element, found in vitamin B12.

Nickel properties enable its use in a range of clean energy technologies including geothermal, as a major cathode material in lithium-ion batteries for EVs and energy storage, hydrogen, hydro, wind, concentrating solar power, nuclear energy technologies, and carbon capture and storage. World Bank relevant low-carbon technologies includes wind, solar photovoltaic, hydro, geothermal, energy storage, nuclear, coal, gas, and carbon capture and storage.

Nickel

Nickel properties enable its use in a range of clean energy technologies including geothermal, as a major cathode material in lithium-ion batteries for EVs and energy storage, hydrogen, hydro, wind, concentrating solar power, nuclear energy technologies, and carbon capture and storage. World Bank relevant low-carbon technologies includes wind, solar photovoltaic, hydro, geothermal, energy storage, nuclear, coal, gas, and carbon capture and storage.

In 2020, the total world production of nickel was 2,500,000 metric tonnes with a 2019 market size of $27B. Nickel provides for a range of desirable attributes including corrosion resistance, high-temperature stability, strength, ductility, toughness, recyclability, as well as catalytic and electromagnetic properties. As a result of these attributes, Nickel is utilized in a wide range of end-use applications including architecture, building & construction, process engineering, food contact materials, energy & power, water, transport, pulp & paper, healthcare, and consumer products.

Nickel is primarily used in alloys where it increases the tensile strength, toughness, and elastic limit. The majority of world nickel production is used in stainless steel, but also for nickel- and copper-based alloys, alloy steels, and in foundries. Ni is one of 4 elements that are ferromagnetic at room temperature and is used in Alnico permanent magnets. Nickel is also used extensively in electroplating, as a binder in cemented tungsten carbides and is naturally magnetostrictive.

As a compound, nickel has numerous niche chemical manufacturing uses including as a catalyst for hydrogenation, cathodes for rechargeable batteries, pigments, and metal surface treatments.

Nickel is an essential nutrient for some microorganisms and plants that have enzymes with nickel as an active site.

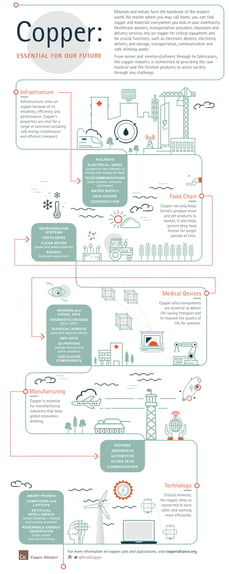

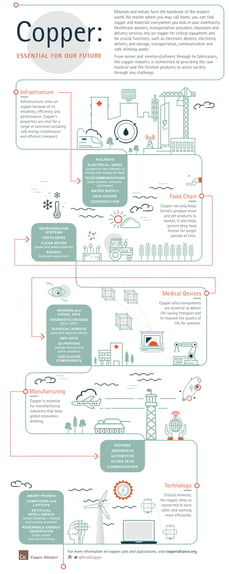

Copper is used up to five times more in renewable energy systems such as solar, wind, tidal, hydro, biomass, and geothermal than in traditional power generation. Because copper is such an excellent thermal and electrical conductor, power systems that utilize copper generate and transmit energy with high efficiency and with minimum environmental impacts. World Bank relevant low-carbon technologies include wind, solar photovoltaic, concentrated solar power, hydro, geothermal, energy storage, nuclear, coal, gas, and carbon capture and storage.

Copper

Copper is used up to five times more in renewable energy systems such as solar, wind, tidal, hydro, biomass, and geothermal than in traditional power generation. Because copper is such an excellent thermal and electrical conductor, power systems that utilize copper generate and transmit energy with high efficiency and with minimum environmental impacts. World Bank relevant low-carbon technologies include wind, solar photovoltaic, concentrated solar power, hydro, geothermal, energy storage, nuclear, coal, gas, and carbon capture and storage.

In 2020, the total world production of copper was 25,000,000 metric tonnes with a 2019 market size of $155B. Copper is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. The major application is for electrical wire where it remains the preferred electrical conductor because of its high electrical conductivity, tensile strength, ductility, creep resistance, corrosion resistance, low thermal expansion, high thermal conductivity, ease of soldering, malleability, and ease of installation. Copper wire is used in power generation, power transmission, power distribution, telecommunications, electronics circuitry, and countless types of electrical equipment

Copper is used extensively as an architectural material due to its corrosion-resistant, low thermal movement, lightweight, lightning protection, and recyclability, and has historically been used in roofs, flashings, rain gutters, downspouts, domes, spires, vaults, doors, and more recently as interior and exterior wall cladding, building expansion joints. Copper’s excellent brazing and soldering properties make it ideal for pipes and joints for plumbing.

Although mostly used as a pure metal, when greater hardness is required, it is used as brass and bronze alloys.

Copper is biostatic, bacteria and many other forms of life will not grow on it. It is therefore antimicrobial and prevents biofouling and is used to line parts of ships to protect against barnacles and mussels, and in the aquaculture industry.

Copper-alloy touch surfaces are approved by the Environmental Protection Agency as “antimicrobial with public health benefits” as they offer natural properties that destroy a wide range of microorganisms and are consequently used for a host of products such as bedrails, handrails, over-bed tables, sinks, faucets, doorknobs, toilet hardware, computer keyboards, health club equipment, and shopping cart handles, including products in healthcare facilities and subway transit systems.

Manganese is a key component of NMC (nickel manganese cobalt) cathode materials for large-scale production of electric vehicle batteries offering low cost, non-toxic, excellent stability and safety, and high cycle durability. World Bank relevant low-carbon technologies include wind, hydro, geothermal, energy storage, coal, gas, and carbon capture and storage.

Manganese

Manganese is a key component of NMC (nickel manganese cobalt) cathode materials for large-scale production of electric vehicle batteries offering low cost, non-toxic, excellent stability and safety, and high cycle durability. World Bank relevant low-carbon technologies include wind, hydro, geothermal, energy storage, coal, gas, and carbon capture and storage.

In 2020, the total world production of manganese was 18,500,000 metric tonnes with a 2019 market size of $40B. Manganese is a transition metal with an array of industrial alloy uses. Steelmaking accounts for nearly 90% of the total manganese demand, as it is essential to iron and steel production by virtue of its sulfur-fixing, deoxidizing, and alloying properties, which avoid “hot shortness”, help to prevent corrosion, make steel more resistant to abrasion, reduces the temperature at which austenite transforms into ferrite, and increases the hardenability rate. Manganese is a key component of low-cost stainless steel.

The second-largest application of manganese is in aluminum alloys where it increases corrosion resistance by absorbing impurities. The largest use for these alloys is for beverage cans, but also for kitchenware, roofing, car radiators, and transportation. Manganese is also used in the fabrication of copper, zinc, magnesium, gold, silver, and bismuth alloy production.

Manganese dioxide is used as a depolarizer in dry-cell battery fabrication, in newer alkaline batteries, and more recently as a component of cathodes in Lithium-Ion batteries.

Other applications include: additive in unleaded gasoline to boost octane rating and reduce engine knocking, a reagent in organic chemistry for the oxidation of benzylic alcohols, for the manufacture of oxygen and chlorine, a pigment for paint, a rubber additive, and an activator in red-emitting phosphors, pigments and for the coloring of ceramics and glass, purifying water, wastewater treatment, odor control, as fungicides in agriculture, in the food industry as a catalyst in the production of artificial flavors such as vanilla, in fertilizers and animal feed, as a ceramic in electronics.

Manganese is also an essential human dietary element, important in macronutrient metabolism, bone formation, and free radical defense systems.

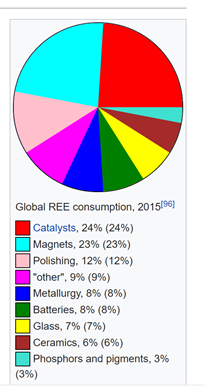

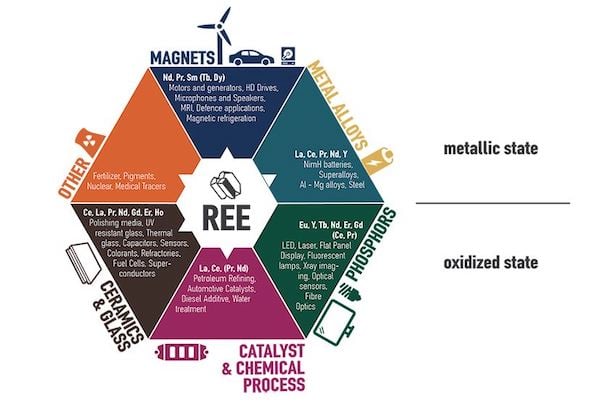

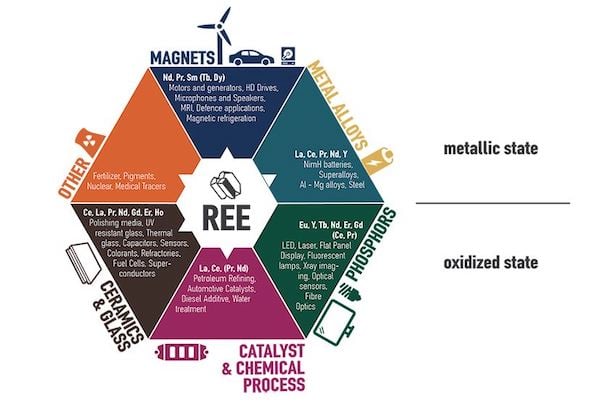

Rare earth elements (REEs) such as Neodymium (Nd) and Dysprosium (Dy) are used in Rare Earth Permanent Magnets (REPMs), offering the strongest magnetic field per volume among all the magnets available in the market. This provides for the most efficient, lightweight and compact, product designs making them indispensable in emerging clean technologies such as wind turbines and electric vehicles (EVs).

Rare Earth Elements

Rare earth elements (REEs) such as Neodymium (Nd) and Dysprosium (Dy) are used in Rare Earth Permanent Magnets (REPMs), offering the strongest magnetic field per volume among all the magnets available in the market. This provides for the most efficient, lightweight and compact, product designs making them indispensable in emerging clean technologies such as wind turbines and electric vehicles (EVs).

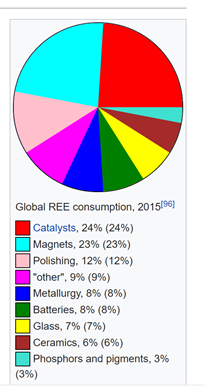

In 2020, the total world production of rare earths was 240,000 metric tonnes with a 2019 market size of $9B. The rare-earth elements (REE) are 17 nearly indistinguishable lustrous silvery-white soft heavy metals, all occurring in the same ore deposits and all exhibiting similar chemical properties, but different electronic and magnetic properties. Most REEs are used for catalysts for petroleum refining and as diesel additives, and for high-performance magnets in electric motors of hybrid and electric vehicles, generators in wind turbines, hard disc drives, portable electronics, microphones, speakers.

The rare earths have diverse applications, semi-finished applications include catalysts, glass, polishing, metal alloys, magnets, phosphors, and ceramics. End products include automatic catalytic converters, fluorescent lamps, wind turbines, electric vehicles, bikes, military weapons, satellite systems, fuel cells, nickel-metal hydride batteries, LCD and plasma screens, fiber optics, lasers, medical imaging, tracers in medical applications, fertilizers, feed additives for livestock, water treatment.

References

Statista, Market size of selected metals worldwide as of August 2019, (in billion U.S. dollars)

Learn More

USGS Minerals Yearbook

Learn More

World Bank

Learn More

Cobalt

Cobalt is a key component of lithium-ion battery cathodes used in the majority of modern electric vehicles. Co provides for high specific power and long-life in electric vehicles, enabling high cycling rate, high capacity, and high power with the lowest self-heating rate of the different types of lithium-ion batteries. World Bank relevant low-carbon technologies include energy storage, coal, gas, and carbon capture and storage.

In 2020, total world production of cobalt was 140,000 metric tonnes with a 2019 market size of $8B. Historically, most cobalt has been used for Co-based superalloys, where it imparts temperature stability making them suitable for turbine blades in gas turbines and aircraft jet engines. Outstanding corrosion- and wear-resistant makes Co-based alloys ideal for orthopedic and dental implants, while increased heat and wear resistance makes Co containing high-speed steels suitable for cutting tool applications. Other specialty alloys containing Co are used to produce Alnico and samarium-cobalt permanent magnets.

Cobalt has been widely used in lithium-ion battery cathodes for consumer electronic devices such as mobile phones, laptops, tablets, power tools, and e-bikes. Nickel-cadmium (NiCd) and nickel metal hydride (NiMH) batteries also include cobalt to improve the oxidation of nickel in the battery. More recently, Co containing lithium-ion batteries have been used in the majority of modern electric vehicle. Their high specific power and long-life are enablers of electric vehicles, providing for high cycling rate, high capacity, and high power with lowest self-heating rate of the different types of lithium-ion batteries.

Cobalt compounds are used as catalysts in the production of polymers, paints, varnishes, inks, hydrodesulfurization of petroleum, and the hydrogenation of carbon monoxide into liquid fuels. They are used to improve the adhesion between steel and rubber in steel-belted radial tires and as accelerators in polyester resin systems.

Cobalt has been used since the Middle Ages as a color for glass and ceramics, and as a pigment for paints, inks and varnishes, and is still used today because of its superior chromatic stability.

Cobalt-60 is useful as a gamma-ray source because it can be produced in predictable amounts with high activity by bombarding cobalt with neutrons. It is used in external beam radiotherapy, sterilization of medical supplies and medical waste, radiation treatment of foods for sterilization, industrial radiography, density measurements, and tank fill height switches.

Other uses include electroplating for its attractive appearance, hardness, and resistance to oxidation, as a base primer coat for porcelain enamels, and Cobalt is also a bio-essential element, found in vitamin B12.

Nickel

Nickel properties enable its use in a range of clean energy technologies including geothermal, as a major cathode material in lithium-ion batteries for EVs and energy storage, hydrogen, hydro, wind, concentrating solar power, nuclear energy technologies, and carbon capture and storage. World Bank relevant low-carbon technologies includes wind, solar photovoltaic, hydro, geothermal, energy storage, nuclear, coal, gas, and carbon capture and storage.

In 2020, the total world production of nickel was 2,500,000 metric tonnes with a 2019 market size of $27B. Nickel provides for a range of desirable attributes including corrosion resistance, high-temperature stability, strength, ductility, toughness, recyclability, as well as catalytic and electromagnetic properties. As a result of these attributes, Nickel is utilized in a wide range of end-use applications including architecture, building & construction, process engineering, food contact materials, energy & power, water, transport, pulp & paper, healthcare, and consumer products.

Nickel is primarily used in alloys where it increases the tensile strength, toughness, and elastic limit. The majority of world nickel production is used in stainless steel, but also for nickel- and copper-based alloys, alloy steels, and in foundries. Ni is one of 4 elements that are ferromagnetic at room temperature and is used in Alnico permanent magnets. Nickel is also used extensively in electroplating, as a binder in cemented tungsten carbides and is naturally magnetostrictive.

As a compound, nickel has numerous niche chemical manufacturing uses including as a catalyst for hydrogenation, cathodes for rechargeable batteries, pigments, and metal surface treatments.

Nickel is an essential nutrient for some microorganisms and plants that have enzymes with nickel as an active site.

Copper

Copper is used up to five times more in renewable energy systems such as solar, wind, tidal, hydro, biomass, and geothermal than in traditional power generation. Because copper is such an excellent thermal and electrical conductor, power systems that utilize copper generate and transmit energy with high efficiency and with minimum environmental impacts. World Bank relevant low-carbon technologies include wind, solar photovoltaic, concentrated solar power, hydro, geothermal, energy storage, nuclear, coal, gas, and carbon capture and storage.

In 2020, the total world production of copper was 25,000,000 metric tonnes with a 2019 market size of $155B. Copper is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. The major application is for electrical wire where it remains the preferred electrical conductor because of its high electrical conductivity, tensile strength, ductility, creep resistance, corrosion resistance, low thermal expansion, high thermal conductivity, ease of soldering, malleability, and ease of installation. Copper wire is used in power generation, power transmission, power distribution, telecommunications, electronics circuitry, and countless types of electrical equipment

Copper is used extensively as an architectural material due to its corrosion-resistant, low thermal movement, lightweight, lightning protection, and recyclability, and has historically been used in roofs, flashings, rain gutters, downspouts, domes, spires, vaults, doors, and more recently as interior and exterior wall cladding, building expansion joints. Copper’s excellent brazing and soldering properties make it ideal for pipes and joints for plumbing.

Although mostly used as a pure metal, when greater hardness is required, it is used as brass and bronze alloys.

Copper is biostatic, bacteria and many other forms of life will not grow on it. It is therefore antimicrobial and prevents biofouling and is used to line parts of ships to protect against barnacles and mussels, and in the aquaculture industry.

Copper-alloy touch surfaces are approved by the Environmental Protection Agency as “antimicrobial with public health benefits” as they offer natural properties that destroy a wide range of microorganisms and are consequently used for a host of products such as bedrails, handrails, over-bed tables, sinks, faucets, doorknobs, toilet hardware, computer keyboards, health club equipment, and shopping cart handles, including products in healthcare facilities and subway transit systems.

Manganese

Manganese is a key component of NMC (nickel manganese cobalt) cathode materials for large-scale production of electric vehicle batteries offering low cost, non-toxic, excellent stability and safety, and high cycle durability. World Bank relevant low-carbon technologies include wind, hydro, geothermal, energy storage, coal, gas, and carbon capture and storage.

In 2020, the total world production of manganese was 18,500,000 metric tonnes with a 2019 market size of $40B. Manganese is a transition metal with an array of industrial alloy uses. Steelmaking accounts for nearly 90% of the total manganese demand, as it is essential to iron and steel production by virtue of its sulfur-fixing, deoxidizing, and alloying properties, which avoid “hot shortness”, help to prevent corrosion, make steel more resistant to abrasion, reduces the temperature at which austenite transforms into ferrite, and increases the hardenability rate. Manganese is a key component of low-cost stainless steel.

The second-largest application of manganese is in aluminum alloys where it increases corrosion resistance by absorbing impurities. The largest use for these alloys is for beverage cans, but also for kitchenware, roofing, car radiators, and transportation. Manganese is also used in the fabrication of copper, zinc, magnesium, gold, silver, and bismuth alloy production.

Manganese dioxide is used as a depolarizer in dry-cell battery fabrication, in newer alkaline batteries, and more recently as a component of cathodes in Lithium-Ion batteries.

Other applications include: additive in unleaded gasoline to boost octane rating and reduce engine knocking, a reagent in organic chemistry for the oxidation of benzylic alcohols, for the manufacture of oxygen and chlorine, a pigment for paint, a rubber additive, and an activator in red-emitting phosphors, pigments and for the coloring of ceramics and glass, purifying water, wastewater treatment, odor control, as fungicides in agriculture, in the food industry as a catalyst in the production of artificial flavors such as vanilla, in fertilizers and animal feed, as a ceramic in electronics.

Manganese is also an essential human dietary element, important in macronutrient metabolism, bone formation, and free radical defense systems.

Rare Earth Elements

Rare earth elements (REEs) such as Neodymium (Nd) and Dysprosium (Dy) are used in Rare Earth Permanent Magnets (REPMs), offering the strongest magnetic field per volume among all the magnets available in the market. This provides for the most efficient, lightweight and compact, product designs making them indispensable in emerging clean technologies such as wind turbines and electric vehicles (EVs).

In 2020, the total world production of rare earths was 240,000 metric tonnes with a 2019 market size of $9B. The rare-earth elements (REE) are 17 nearly indistinguishable lustrous silvery-white soft heavy metals, all occurring in the same ore deposits and all exhibiting similar chemical properties, but different electronic and magnetic properties. Most REEs are used for catalysts for petroleum refining and as diesel additives, and for high-performance magnets in electric motors of hybrid and electric vehicles, generators in wind turbines, hard disc drives, portable electronics, microphones, speakers.

The rare earths have diverse applications, semi-finished applications include catalysts, glass, polishing, metal alloys, magnets, phosphors, and ceramics. End products include automatic catalytic converters, fluorescent lamps, wind turbines, electric vehicles, bikes, military weapons, satellite systems, fuel cells, nickel-metal hydride batteries, LCD and plasma screens, fiber optics, lasers, medical imaging, tracers in medical applications, fertilizers, feed additives for livestock, water treatment.

References

Statista, Market size of selected metals worldwide as of August 2019, (in billion U.S. dollars)

Learn More

USGS Minerals Yearbook

Learn More

World Bank

Learn More

Is There a Market for Seabed Nodule Mining?

As international mandates drive EV adoption and global auto manufacturers commit to fleet electrification, the supply of cobalt, nickel and other key resources will become the focus of global government and business interests alike. Amplified by declining grades and a lack of new sizeable land-based mines, coupled with increased ESG requirements, enormous growth in demand for these metals and upward price pressure are sure to follow. These factors all support a strong market for seabed nodule mining.